A pressure washer’s pump is the heart of the machine, responsible for generating the water pressure necessary to clean surfaces effectively. Over time, even the most reliable pumps can wear out, malfunction, or break down. When that happens, knowing how to troubleshoot and repair your pressure washer pump can save you time and money. In this article, we’ll walk you through common pump problems and the steps you can take to repair or replace a faulty pump.

1. Identifying Pressure Washer Pump Problems

Before diving into the repair process, it’s important to understand the most common issues that can affect a pressure washer pump. Some signs of a failing pump include:

- Low Water Pressure: If the pump isn’t building up enough pressure, your cleaning power will suffer.

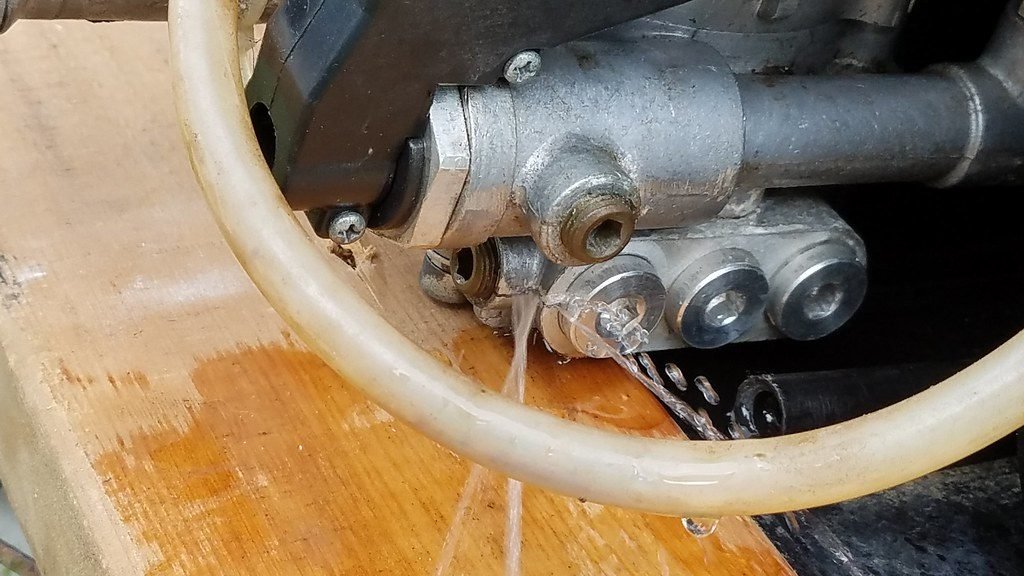

- Water Leaks: Leaks around the pump housing indicate that seals or components inside the pump may be damaged.

- Strange Noises: Grinding or whining noises coming from the pump can be a sign of internal damage.

- Overheating: A pump that gets excessively hot or shuts off suddenly might be struggling to maintain pressure.

- Complete Failure: If your pressure washer isn’t pumping water at all, the pump might have seized or broken entirely.

2. Basic Troubleshooting for Pressure Washer Pump Problems

Before diving into any major repairs, you’ll want to rule out simple causes of pump problems. Here are a few basic steps to try:

- Check Water Supply: Make sure your water supply is adequate. Without sufficient water pressure, the pump won’t work correctly. A minimum flow of 20 PSI is usually required.

- Inspect Hoses: Ensure that the high-pressure hose and water inlet hose are free from kinks, blockages, and leaks.

- Clean the Nozzle: A clogged nozzle can restrict water flow, leading to low pressure. Remove and clean the nozzle with a needle or nozzle cleaning tool.

- Examine the Unloader Valve: If the unloader valve is stuck or malfunctioning, it can cause low pressure or complete pump failure. Clean and adjust the valve if necessary.

If these basic steps don’t solve the problem, the issue is likely within the pump itself, requiring further investigation.

3. Disassembling the Pressure Washer Pump

If the problem lies inside the pump, you’ll need to disassemble it to perform a repair. Follow these steps to safely open the pump:

- Turn Off the Power: Always disconnect the pressure washer from its power source (for electric models) or remove the spark plug wire (for gas models) before beginning repairs.

- Remove the Pump Housing: Use a wrench to loosen the bolts that hold the pump housing to the pressure washer. Carefully remove the pump from the unit.

- Inspect the Pump: Look for visible signs of damage, such as worn-out seals, cracked pistons, or broken components. If any parts appear damaged, they will need to be replaced.

4. Replacing Worn Seals and O-Rings

Seals and O-rings inside the pump are responsible for keeping water contained and pressure consistent. Over time, these components can wear out, leading to leaks or loss of pressure.

- Purchase a Seal/O-Ring Repair Kit: Many manufacturers offer seal and O-ring repair kits specifically designed for pressure washer pumps.

- Replace Seals: Remove the old seals and O-rings from the pump, taking note of where each one is located. Install the new seals in the same positions, ensuring a tight fit to prevent future leaks.

- Reassemble the Pump: Once the new seals are in place, reassemble the pump and secure it to the pressure washer. Test the unit to ensure it’s functioning properly.

5. Repairing or Replacing Pump Valves

Pump valves control the flow of water into and out of the pump. If these valves become damaged or clogged with debris, your pressure washer may lose pressure or fail to pump water altogether.

- Remove the Pump Valves: Use a wrench to unscrew the pump valves from the pump housing. Inspect each valve for signs of damage or blockage.

- Clean or Replace Valves: If the valves are simply clogged, clean them thoroughly and reinstall them. If they are damaged, replace them with new valves from a repair kit.

Tip: Regular maintenance and cleaning can help prevent valve failure.

6. Replacing Pump Pistons or Plungers

Pistons or plungers inside the pump create pressure by moving back and forth. If these components are cracked, worn, or seized, they will need to be replaced.

- Remove the Pump Pistons/Plungers: Disassemble the pump housing to access the pistons or plungers. Use a wrench to remove the old pistons.

- Install New Pistons/Plungers: Insert new pistons or plungers, ensuring they are properly aligned. Reassemble the pump and test for proper operation.

7. Repairing or Replacing the Pump Head

The pump head is the part of the pump that houses the pistons, seals, and valves. If the pump head becomes cracked or damaged, it may need to be replaced.

- Inspect the Pump Head: Look for visible cracks or damage. A cracked pump head will usually need to be replaced entirely.

- Replace the Pump Head: Purchase a compatible replacement pump head for your pressure washer model. Remove the old pump head and install the new one, ensuring a proper fit.

8. When to Replace the Pump Entirely

If your pump has extensive internal damage, it may be more cost-effective to replace the pump entirely rather than repairing individual components. Many pressure washers allow for easy pump replacement.

- Purchase a Replacement Pump: Look for a pump that matches the specifications of your pressure washer model.

- Install the New Pump: Follow the manufacturer’s instructions to install the new pump and reconnect it to the pressure washer.

Replacing a pump can often breathe new life into an older machine, especially if other components are still functioning well.

9. Preventative Maintenance to Avoid Pump Damage

To keep your pressure washer pump in good condition and avoid costly repairs in the future, it’s essential to practice regular preventative maintenance. Here are some key tips:

- Use Clean Water: Always ensure that your water supply is clean and free from debris. Dirty water can cause clogs and damage pump components.

- Flush After Use: After using your pressure washer, flush it with clean water to remove any remaining detergent, dirt, or debris from the system.

- Store Properly: Store your pressure washer in a dry, temperature-controlled environment to prevent freezing, rust, or damage to seals and components.

- Use Pump Oil: Regularly check and change the pump oil (if applicable) according to the manufacturer’s recommendations.

10. Professional Pump Repair and Replacement Services

If you’re unable to repair your pump yourself or if you’re unsure about the extent of the damage, it might be best to consult a professional. For residents of Los Angeles, California, Painters Easy Cali offers expert pressure washer repair services. We’ll diagnose the problem and either repair or replace your pump to restore full functionality.

Conclusion: Don’t Let a Broken Pump Slow You Down

A malfunctioning pump can significantly reduce the effectiveness of your pressure washer, but most issues can be repaired with the right tools and knowledge. By following the steps outlined in this guide, you can diagnose, repair, or replace your pressure washer pump and get back to cleaning.

If you’re looking for professional help, or if your pump needs replacing, Painters Easy Cali in Los Angeles is here to assist you with all your pressure washing needs. Contact us today!

Leave a Reply